Products and Plants

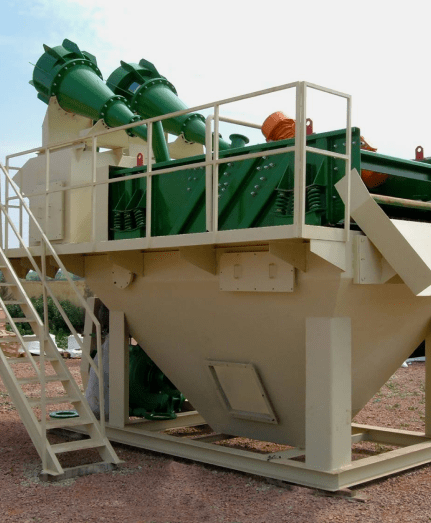

Hydro cyclone sand washing plant with dewatering screen

Hydro cyclone with dewatering screen is a common tool in the mining industry, it can be widely used in mines, ore, slurry, sand washing plant, sand production plant, mine, construction, concrete mixing plant, etc. In Convotech Engineering LLP, we also called the dewatering screen with a cyclone as a sand recycling machine.

Sand washing machine is an indispensable tool in sand and gravel processing plant. But you should all know that there is a big defect in the sand washing machine, which is the loss of serious fine materials.

Hydro cyclone with dewatering screen is designed to solve the above problem that leaves the sand washing machine, as the name implies, devices that are mainly composed of vibrating dewatering screen and cyclone. Hence, we also call it fine sand recycling machine. The amount of fine sand loss can therefore be controlled within 5%, which can solve the fineness of the finished sand and the partiality of the stone powder in the artificial aggregate processing system.

Product details

Explore hydrocyclone separation and it’s efficiency with dewatering screens

A hydrocyclone separator is an integral component of a hydrocyclone sand washing plant. Do you want to know how it works and what it does in conjunction with a dewatering screen to clean and dehydrate your sand? Well, it’s quite simple! The hydrocyclone’s centrifugal force is used to separate sand from water. The sand is evacuated while the water is collected and reused, resulting in excellent cleaning. Dewatering in construction is used to manage groundwater levels and lessen groundwater pressures on subsurface structures.

Wellpoints, sump pumps, eductor wells, and deep wells are the four primary types of dewatering systems. Each dewatering process is better suited to certain excavations and soil types. Its primary applications are dewatering, desliming, and desulphurization. Slime dewatering screens, sand dewatering screens, high-frequency dewatering screens, and tailings dewatering screens are all types of dewatering screen equipment.

Following a few easy rules will help you boost hydrocyclone efficiency. Regular maintenance keeps it in good working order. Adjusting the hydrocyclone settings to match your specific needs and using high-quality equipment from reputable hydrocyclone sand washing manufacturers may have a significant impact. This ensures that your sand-washing procedure is both successful and economical.

Technical data of Hydro Cyclone with Dewatering Screen

| Hyadro cylone with dewatering screen Cap. 30 TO 50 TPH (MODEL: CTE/ECO 50) | |

|---|---|

| Technical data of cyclone | |

| Cyclone Body Diameter | Ø 300 mm |

| Cyclone Height | 1454 mm |

| Vortex Finder Size | Ø 169 mm |

| Inlet Type | Spiral |

| Inlet Pipe Size | 200 mm |

| Overflow Pipe Size | 191 mm |

| Possible Apex / Spigot Sizes | Ø 55 mm/65mm/75mm |

| Recommended Operating Pressure | 0.9 to 1.3 bar |

| Recommended Slurry Feed Flow | 20 m3/hr |

| Recommended Feed Range | Up to 5 mm |

| Recommended Overflow Range | Up to 150 microns |

| Technical data of centrifugal pump | |

| Pump type | Horizontal Centrifugal Pump |

| Pump Model | 3X2 |

| Suction & Discharge size in mm | 75 X 50 |

| Quantity | 1 no. |

| Liquid Handled | Slurry Water |

| Capacity in ‘m3/hr’ | 35 |

| Pump Speed in RPM | 1250 |

| Motor | 7.5 kw, 3 PHASE, 440 V, 1440 rpm |

| Make | Crompton /ABB/Bharat Bijli |

| Impeller | 4 Vanes Closed |

| Drive Arrangement | Belt Drive |

| technical data of dewatering screen | |

|---|---|

| Screen Size | 1200X2100 mm long |

| Screen Capacity | 30 TO 50 TPH |

| Operating Angle of Screen | -4 ˚ degree |

| Screen | Pu mesh |

| Vibrating Pad | Rubber pad |

| MOTOR | |

| Power | 2 + 2 (4 hp),3 PHASE, 440 V, 1400 rpm |

| Make | Sai deep / oli German |

| Structure | FABRICATED FROM M.S. PIPE, 8MM PLATE ISMC & ISA, AS PER CTE STANDARD DESIGN |

| Discharge Chute | Provided |

| Hyadro cylone with dewatering screen Cap. 80 TO 100 TPH (MODEL: CTE/ECO 100) | |

|---|---|

| Technical data of cyclone | |

| Cyclone Body Diameter | Ø 400 mm |

| Cyclone Height | 1854 mm |

| Vortex Finder Size | Ø 184 mm |

| Inlet Type | Spiral |

| Inlet Pipe Size | 200 mm |

| Overflow Pipe Size | 191 mm |

| Possible Apex / Spigot Sizes | Ø 55 mm/65mm/75mm |

| Recommended Operating Pressure | 0.9 to 1.3 bar |

| Recommended Slurry Feed Flow | 65 m3/hr |

| Recommended Feed Range | Up to 4 mm |

| Recommended Overflow Range | Up to 150 microns |

| Technical data of centrifugal pump | |

| Pump type | Horizontal Centrifugal Pump |

| Pump Model | 4X3 |

| Suction & Discharge size in mm | 100 X 80 |

| Quantity | 1 no. |

| Liquid Handled | Slurry Water |

| Capacity in ‘m3/hr’ | 100 |

| Pump Speed in RPM | 1250 |

| Motor | 20 hp/ 15 kw, 3 PHASE, 440 V, 1440 rpm |

| Make | Crompton /ABB/Bharat Bijli |

| Impeller | 6 Vanes Closed |

| Drive Arrangement | Belt Drive |

| Technical data of dewatering screen | |

|---|---|

| Screen Size | 1500X3000 mm long |

| Screen Capacity | 80 TO 100 TPH |

| Operating Angle of Screen | -4 ˚ degree |

| Screen | Pu mesh |

| Vibrating Pad | Rubber pad |

| Motor | |

| Power | 3 + 3 (6 hp),3 PHASE, 440 V, 1400 rpm |

| Make | Sai deep / oli German |

| Structure | FABRICATED FROM M.S. PIPE, 8MM PLATE ISMC & ISA, AS PER CTE STANDARD DESIGN |

| Discharge Chute | Provided |

| Hyadro cylone with dewatering screen Cap. 120 TO 150 TPH (MODEL: CTE/ECO 150) | |

|---|---|

| Technical data of cyclone | |

| Cyclone Body Diameter | Ø 500 mm |

| Cyclone Height | 1910 mm |

| Vortex Finder Size | Ø 224 mm |

| Inlet Type | Spiral |

| Inlet Pipe Size | 200 mm |

| Overflow Pipe Size | 191 mm |

| Possible Apex / Spigot Sizes | Ø 55 mm/65mm/75mm |

| Recommended Operating Pressure | 0.9 to 1.3 bar |

| Recommended Slurry Feed Flow | 130 m3/hr |

| Recommended Feed Range | Up to 4 mm |

| Recommended Overflow Range | Up to 150 microns |

| Technical data of centrifugal pump | |

| Pump type | Horizontal Centrifugal Pump |

| Pump Model | 6X4 |

| Suction & Discharge size in mm | 150 X 100 |

| Quantity | 1 no. |

| Liquid Handled | Slurry Water |

| Capacity in ‘m3/hr’ | 120 |

| Pump Speed in RPM | 1250 |

| Motor | 27 hp/20 kw, 3 PHASE, 440 V, 1440 rpm |

| Make | Crompton /ABB/Bharat Bijli |

| Impeller | 6 Vanes Closed |

| Drive Arrangement | Belt Drive |

| Technical data of dewatering screen | |

|---|---|

| Screen Size | 1800X3000 mm long |

| Screen Capacity | 120 TO 150 TPH |

| Operating Angle of Screen | -4 ˚ degree |

| Screen | Pu mesh |

| Vibrating Pad | Rubber pad |

| Motor | |

| Power | 4 + 4 (8 hp),3 PHASE, 440 V, 1400 rpm |

| Make | Sai deep / oli German |

| Structure | FABRICATED FROM M.S. PIPE, 8MM PLATE ISMC & ISA, AS PER CTE STANDARD DESIGN |

| Discharge Chute | Provided |

| Hyadro cylone with dewatering screen input cap. 200-250 TPH (MODEL: CTE/ECO 250) | |

|---|---|

| Technical data of cyclone | |

| Cyclone Body Diameter | Ø 500 mm |

| Cyclone Height | 2000 mm |

| Vortex Finder Size | Ø 224 mm |

| Inlet Type | Spiral |

| Inlet Pipe Size | 200 mm |

| Overflow Pipe Size | 191 mm |

| Possible Apex / Spigot Sizes | Ø 55 mm/65mm/75mm |

| Recommended Operating Pressure | 0.9 to 1.3 bar |

| Recommended Slurry Feed Flow | 370 m3/hr |

| Recommended Feed Range | Up to 4 mm |

| Recommended Overflow Range | Up to 150 microns |

| Technical data of centrifugal pump | |

| Pump type | Horizontal Centrifugal Pump |

| Pump Model | 6X4 |

| Suction & Discharge size in mm | 150 X 100 |

| Quantity | 1 no. |

| Liquid Handled | Slurry Water |

| Capacity in ‘m3/hr’ | 370 |

| Pump Speed in RPM | 1250 |

| Motor | 60hp/45 kw, 3 PHASE, 440 V, 1440 rpm |

| Make | Crompton /ABB/Bharat Bijli |

| Impeller | 6 Vanes Closed |

| Drive Arrangement | Belt Drive |

| Technical data of dewatering screen | |

|---|---|

| Screen Size | 2400X3500 mm long |

| Screen Capacity | 200-250 TPH |

| Operating Angle of Screen | -4 ˚ degree |

| Screen | Pu mesh |

| Vibrating Pad | Rubber pad |

| Motor | |

| Power | 15 + 15 (30 hp), 3 PHASE, 440 V, 1400 rpm |

| Make | Sai deep / oli German |

| Structure | FABRICATED FROM M.S. PIPE, 8MM PLATE ISMC & ISA, AS PER CTE STANDARD DESIGN |

| Discharge Chute | Provided |

Get In touch

Contact Us Anytime for Help!

Convotech Engineering is synonymous with advanced engineering, cost-effectiveness, innovative thinking and custom-made solutions. We are fast emerging as a most sought-after brand in the construction and mining sectors, both in Indian and international markets.

Years

3+

Sales

200+

exports